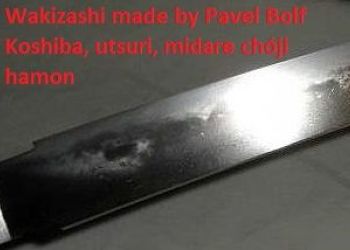

Utsuri

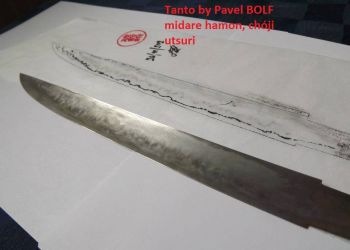

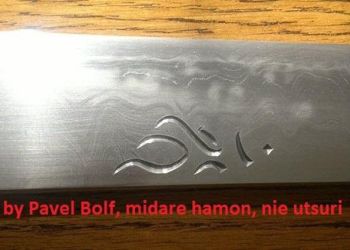

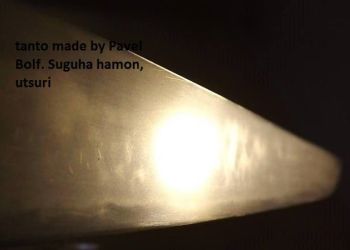

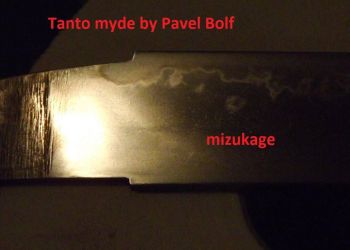

secondary hardening effect on Japanese sword blades

Pavel Bolf

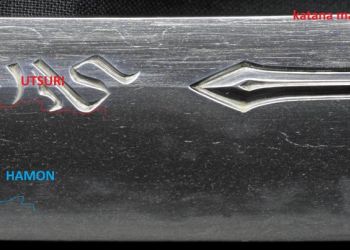

The primary intention of the swordsmith in the hardening process is to create a hard, cloudy HAMON blade line. The UTSURI line, which usually appears as a shadow following the HAMON line, is one of the secondary metallurgical manifestations of hardening on the blade. UTSURI is a typical feature of high quality KOTO blades (pre-1600), especially blades made in the KAMAKURA period. On the other hand, it is very rare on swords made after 1600. This may be a result of the change in requirements for swords. More emphasis was placed on the attractive HAMON line, which may have led to the development of new processes and technologies needed to satisfy these demands. The old processes of which UTSURI was a product were then forgotten over time.

What is UTSURI? I have come across the notion that UTSURI may be the boundary between the differently processed steel used for the blade edge and the blade sides. The different carbon content and steel texture resulting from the reloading process creates a visually distinct line on some swords. The steel of the blade is usually darker and has a finer texture (HADA, JIGANE). If the HAMON hardening line reaches a lower height than that of the different steel used for the blade, this different steel creates a darker line above the HAMON line. However, this is not UTSURI in my opinion. It is merely a difference in the quality of the various steels used in the blade construction. For example, in SAN MAI type designs. This effect arises depending on the processing of the steel, during the forging of the blade. The difference in the colour and shade of the steel is due to the different carbon content or the different folding structure. (Figure 29)

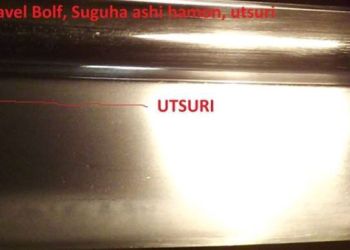

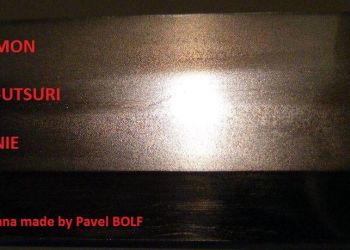

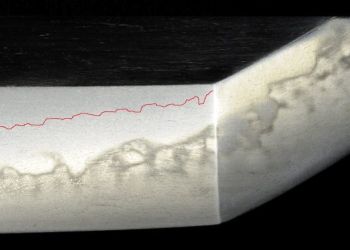

In contrast, UTSURI is the effect that occurs when the blade is hardened. The structure of the steel in the UTSURI area is different from the rest of JIGANE. The steel particles are denser, more compact. (Figure 1) In some cases, there are scattered particles of NIE in the UTSURI that are reflective to light. Sometimes they can be observed throughout the UTSURI, sometimes only near its upper edge, where they form a continuous band or islands with varying densities of these radiant particles. In this case, it is a NIE UTSURI. (Figure 20, 21, 23) UTSURI is a manifestation of sensitivity, the sensitivity of the blade to heat treatment. Not every steel is capable of producing UTSURI. Therefore, the ability of steel to form UTSURI is influenced by the production of the raw material itself - the steel. It does not matter whether the steel is made from ore (TAMAHAGANE) or recycled steel (OROSHIGANE). The subsequent processing of the steel, its cleaning and homogenisation by means of the reloading technique obviously has a major influence on the quality of the resulting steel and its ability to produce the required HAMON line and secondary hardening marks (HATARAKI), including UTSURI. Sensitive steel is capable of forming several types of UTSURI on one blade above the HAMON line with the correct quenching procedure. The quenching procedure is an essential step for the formation of UTSURI. It is possible to achieve this effect both when quenching without using paste (ZUBU YAKI) and when using clay. In both cases, different types of UTSURI are possible, but the steel must always be respected. Some hardening methods do not allow the formation of UTSURI, although they can result in a beautiful HAMON line. There are many types of UTSURI. Some types of UTSURI contain additional metallurgical activities. Their intensity can vary. It is very interesting to study these metallurgical changes in steel under good light. Sometimes the UTSURI appears only as a dark shadow or dark areas above the HAMON line. The contrast, the intensity of the darker coloration may vary. (Figure 8, 9, 11)

For clearly delineated dark areas, please do not confuse with NAMAZU HADA. In this case it is the structure of the steel. It is similar to the embedded steel forming the blade.

Shape UTSURI differs similarly to the hardening line of HAMON. The straight line above HAMON is BO- UTSURI. (Figure 5) The CHÓJI-UTSURI is similar in shape to the CHÓJI HAMON. (Figure 22) The shape of the UTSURI does not have to match the HAMON type. A blade with an active CHÓJI HAMON may have a BO-UTSURI. Likewise, above the straight line of a SUGUHA type HAMON, the UTSURI may be distinctly wavy. It depends on the steel and the method of clouding. The possibilities of influencing the type and shape of the UTSURI are not as extensive as with the HAMON quenching line. Also, the aspects that influence the formation of UTSURI are much more numerous and their interaction is considerably more complicated.

I have an experience where I used the same (processed) steel for two TANTO blades. I performed hardening in the same way with the intention of creating a SUGUHA type HAMON hardening line with ASHI. The hardening was successful. The ASHI was less pronounced on the first blade. The UTSURI line, on the other hand, was very distinct, of the MIDARE UTSURI type, bordered by distinct clusters of NIE particles. (Figure 25) The second blade has distinct ASHI in the HAMON, CHOJI UTSURI, and no NIE particles. I forged a third small blade from the rest of the steel. I performed the quenching in a different way, with the intention of creating a CHÓJI HAMON with distinctive NIE particles. Again, a UTSURI was formed. Less pronounced MIDARE UTSURI, without NIE.

A MIZUKAGE was also formed, bordered by a subtle NIE. It is interesting to study how even very small differences in steel preparation and hardening affect the resulting blade metallurgy.

MIZUKAGE is an effect that is created above the beginning of the HAMON line (at HAMACHI). It appears as an oblique shadow. (Figure 24) There are opinions that it is a shadow after the blade has been plunged into the water during hardening. This is only one possibility. More often it is more likely to be the edge of the blade heating. The temperature range that affected the structure and properties of the steel prior to hardening. It is actually a type of UTSURI. MIZUKAGE is sometimes referred to in the literature as a blade defect. This may only apply to SURIAGE, shortened blades. There, it's an indication that the blade is over-forged. In a new blade in its original length, it cannot be a flaw. On the contrary, it is a natural manifestation of the sensitivity of the steel.

An interesting part of UTSURI is the KOSHIBA effect. (Figure 25, 26, 27) It appears as a cluster of reflective particles at the beginning of UTSURI. Again, this is an effect of the extreme sensitivity of the steel to the quenching process. The KOSHIBA effect appears on fine 12th-13th century blades.